REMOTE HYDRAULIC MINING CANNONS

PROJECT

Queensland Hydraulic Mining Operation

OBJECTIVE

XR3 upgraded its proprietary hydraulic mining cannons to fully remoted controlled for a Queensland operation. The objective was to leverage existingtechnology in an innovative manner to maximise operational uptime and improvetailings reprocessing efficiency while reducing personnel exposure and enabling supervisors to focus on broader operational priorities, delivering safer and more reliable operations.

THE CHALLENGES

XR3 faced operational constraints that limited tailings processing efficiency and risked interruptions to uptime.

- Safety Risks – Personnel exposed to hazardous conditions during adverse weather or unstable ground.

- Weather & Site Interruptions – Conditions forcing shutdowns, reducing throughput.

- Limited Oversight Capacity – Supervisors were tied to monitoring operations, limiting their ability to be proactive.

APPROACH

- Technology Development & Deployment – Development and deployment of remote hydraulic mining cannons designed to operate safely from a climate-controlled control room up to 1.5 km from the tailings facility.

- Remote Operational Control – Development and deployment of remote hydraulic mining cannons designed to operate safely from a climate-controlled control room up to 1.5 km from the tailings facility.

- Safety & Risk Mitigation – Implementation of enhanced safety controls and exclusion zones to reduce personnel access to hazardous areas while maintaining operational continuity.

- Operational Planning – In-house engineering supported operational planning and sequencing to meet geotechnical requirements, maintain slurry solids, optimise sump placement, and maximise throughput.

- Performance Monitoring & Optimisation – Continuous monitoring and performance optimisation through weekly data review, operator feedback, and adjustments to short-term planning to sustain consistent throughput.

- Supervisory Enablement – Empowering supervisors to focus on inspections, troubleshooting, and other site priorities by reducing their direct monitoring of cannon operations.

RESULTS

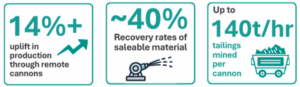

The introduction of XR3’s remote hydraulic mining cannon delivered measurable improvements at the operation:

- 14% increase in average daily production, equivalent to over 6,000 extra tonnes per month

- ~40% recovery of saleable material from tailings, demonstrating the effectiveness of XR3’s hydraulic mining methodology

- Sustained mining rate of up to ~140 tonnes per hour per cannon

- Operators manage plant performance remotely, improving decision-making and control

- Reduced operator fatigue and exposure to harsh environmental conditions

The remote cannon has proven to be a key driver of productivity, safety, and operational efficiency.