PELLETISING

Pelletising is a process we implement to manage and process reclaimed tailings. The pelletising process converts these fine materials into small, solid pellets, which can then be sold.

Resource Recovery

Pelletising tailings allows businesses to recover valuable minerals and metals that may have been overlooked during the initial extraction process. This can lead to new revenue streams and a more efficient use of resources.

Environmental Benefit

By converting tailings into pellets, mining operations can significantly reduce the volume of waste stored in tailings dams.

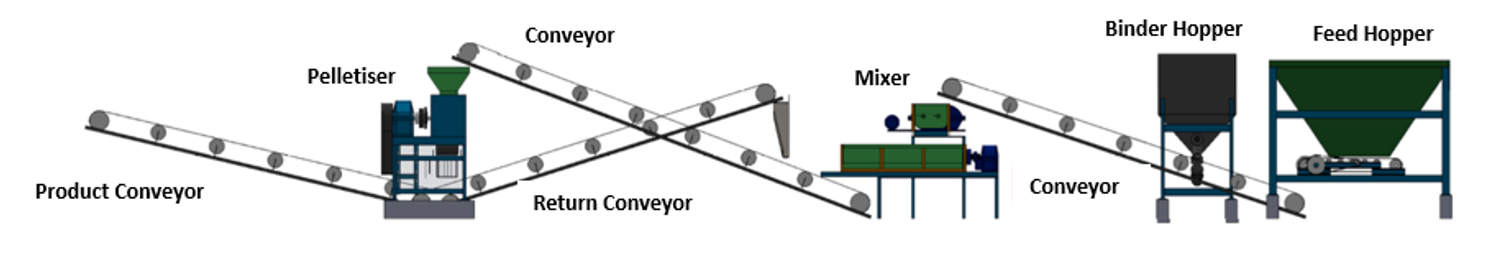

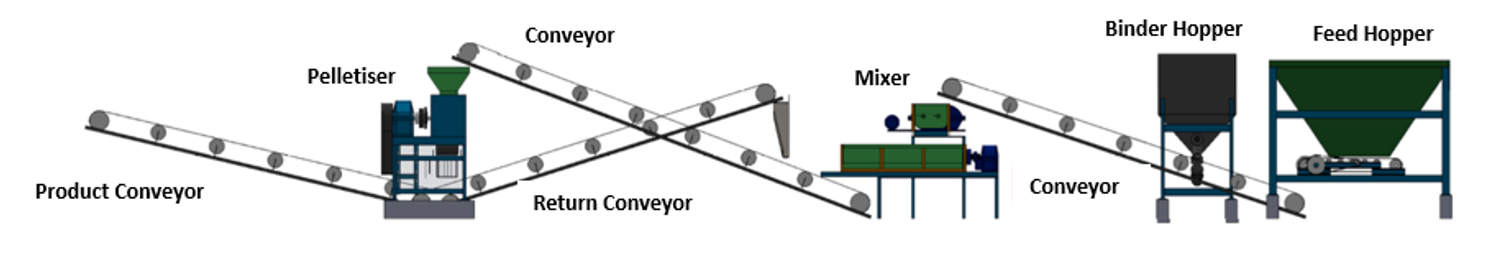

Modular Design

XR3 offer a modular design of equipment for simple site establishment and scale-up.

Full Turnkey Solution

XR3 has a proven track record of successfully delivering innovative mining practices in Queensland coal mines. We are able to deliver a full turnkey solution for your tailings reclamation needs.

Strength of Material

Drop-shatter tests to simulate materials handling showed minimal breakage of the pellets with less than 4% of material passing 5mm.

Broad range of feed moistures possible, with minimal impact on pellet strength or breakage.

Reclaimed tailings or process tailings are mixed with binders and water (if required). The tailings and binder mix are fed into a multi-step pelletising unit which reduces malformed pellets. The pellets are compressed and discharged to a fines screen which recovers any non-pelletised material that is returned to the process. Pellets are discharged and processed according to the clients requirements.