HYDRAULIC MINING

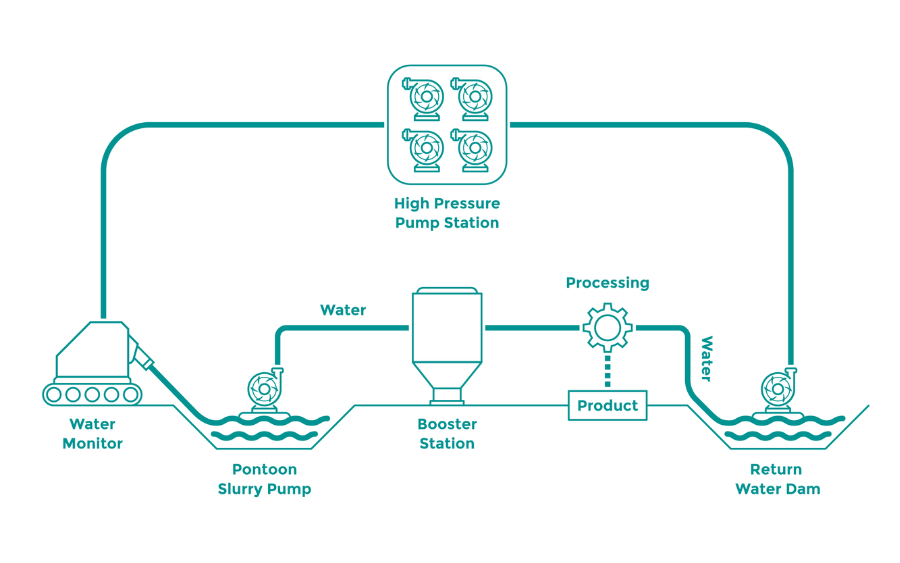

We offer comprehensive hydraulic mining services to extract minerals from tailings with precision and efficiency. Our expertise ranges from the supply of hydraulic cannons to the installation and day-to-day operation of hydraulic mining systems across Australia and internationally.